Electrek has learned more about Tesla’s secret project “Roadrunner”: applying “the machine that builds the machine” strategy to produce cheaper battery cells on a massive scale.

$100 per kWh has been described as the price target for batteries to enable electric vehicles to reach a price parity with gasoline cars without subsidies.

If combined with mass production, it’s considered the “holy grail” of EV adoption since it would enable high-volume production of relatively affordable and/or high-margin electric cars.

Tesla’s partnership with Panasonic has led to an industry-leading battery cost, but the automaker is looking to take things a step further by making its own cells.

For a few months now, Tesla has been rumored to be working on making its own battery cells for its electric vehicles.

It started with the acquisition of Maxwell, a supercapacitor manufacturer with some battery cell technology, and later, at its annual shareholder’s meeting, Tesla all but confirmed that it’s going to manufacture its own battery cells.

Later, we reported that Tesla referred to battery cells as a new “product line” for the company in some job listings for cell manufacturing.

Earlier this month, we shared an exclusive report about Tesla building a battery cell pilot production line in Fremont.

Now sources have told Electrek that the secret project is called “Roadrunner,” and it will aim to achieve mass production of a new battery cell that will be more energy-dense and cheaper.

The cells are using technologies developed by Tesla’s internal teams, including work from its research lab in Canada led by Jeff Dahn, and new technologies recently acquired through the acquisition of Maxwell.

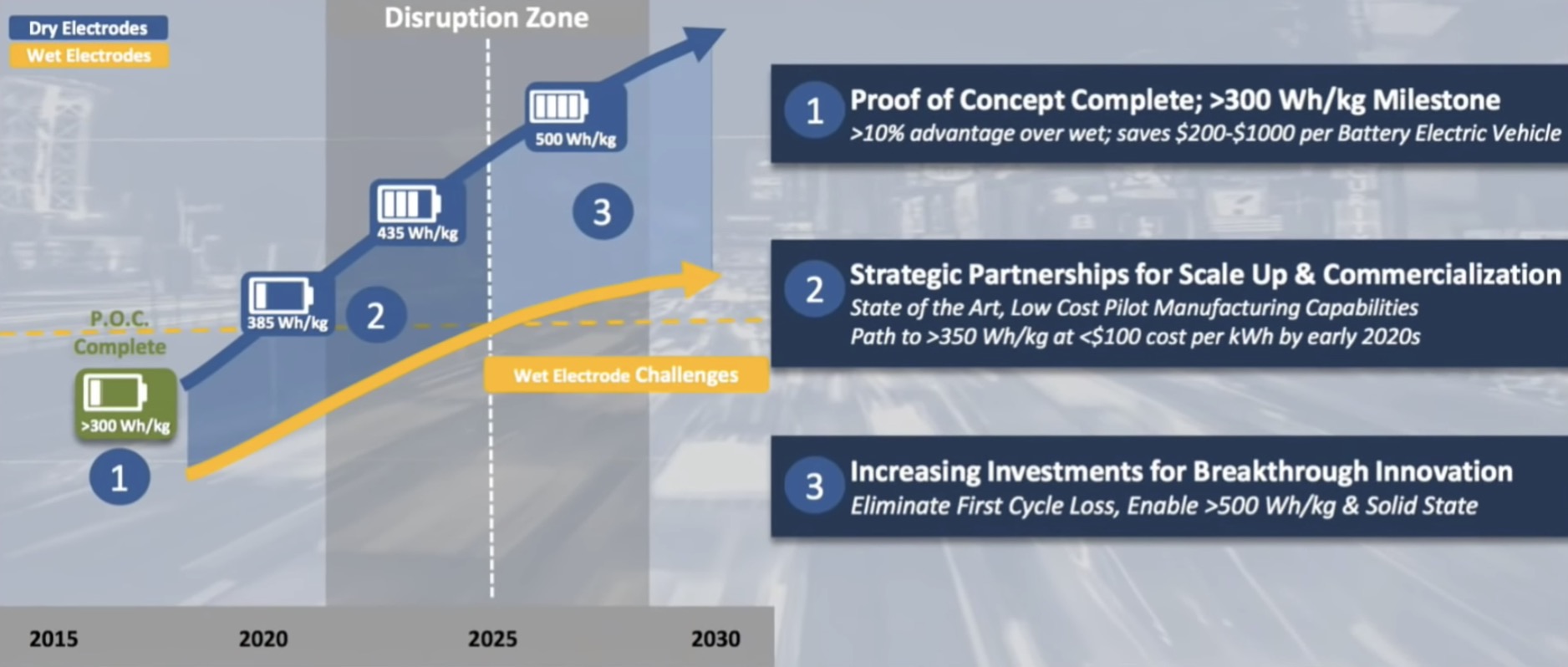

Maxwell’s dry electrode technology would enable Tesla to produce cheaper cells with higher-energy density that would enable them to use less batteries per vehicle and still achieve longer range:

Tesla has already tested prototype cells under the Roadrunner secret project. It believes it can produce the cells in volume and use them in its vehicles and eventually in its stationary energy storage products.

The automaker has been developing manufacturing equipment in secrecy, like the pilot production line in Fremont, over the last few months.

Some Tesla engineers have briefly mentioned the new battery cell in comments on LinkedIn found by Electrek.

Tesla staff R&D engineer Matthieu Moors asked engineers to join the team to “reinvent” cell manufacturing:

Come join us and reinvent Li-Ion battery cell manufacturing technology!

Bonne Eggleston, senior manager of cell manufacturing, commented:

Developing world-class battery cell manufacturing technologies to enable the next generation of low-cost, high-performance electric vehicles and energy storage products.

With the introduction of the new battery cells, Tesla is also working on new module and battery pack improvements, according to sources talking to Electrek.

It includes moving away from wire bonding on the cells and going with a laser-welded technology instead.

Tesla president of autopilot Jerome Guillen said on LinkedIn that the battery module team is “central to the secret sauce at Tesla”:

We continue to hire! In particular, for battery module mechanical design engineer. It is hard to think of a position more central to the secret sauce at Tesla. The battery module team is particularly awesome and smart.

One source told Electrek that CEO Elon Musk is pushing to have one of those new battery packs with the new Tesla-made battery cells ready to install in a Model S or Model X for the “Battery Investor Day” in April.

More information is going to be released at the event where Tesla is expected to announce the production of the cells in the US, Europe, and China.