Amidst Tesla’s continued efforts to usher in an era of mobility optimized for the convenience and safety of car owners, the electric car maker is exploring new ways to improve its vehicles’ systems. Recently published patent applications, for one, indicate that Tesla is working on better damage monitoring features, as well as safer seats that are capable of classifying a car’s occupants. Apart from these, Tesla is also looking into improving its vehicles’ electric pump system, which could ultimately result in better cooling and diagnostics.

The patent application, published on January 3, 2019 and titled “Electric Pump System and Method,” explores improvements that could be implemented on traditional pump systems used in automobiles. As noted by Tesla, traditional oil pumps, particularly those that are used for EV components such as the drive unit, do not have the capability to monitor oil condition. As a result, oil that is used to lubricate an electric car’s drive unit need to be changed on a regular basis (albeit very infrequently).

In the discussion section of its patent application, Tesla pointed out that traditional oil pumps are unable to accurately determine temperature, since temperature sensors are usually located outside of a conventional pump system. Apart from this, the electric car maker notes that conventional oil pumps are also large and unwieldy due to attachment mechanisms comprised of different parts. With these points for improvement in mind, Tesla has pointed out that there is a need for an “improved oil pump — in particular an electric pump system — designed to work in conjunction with an electric motor.”

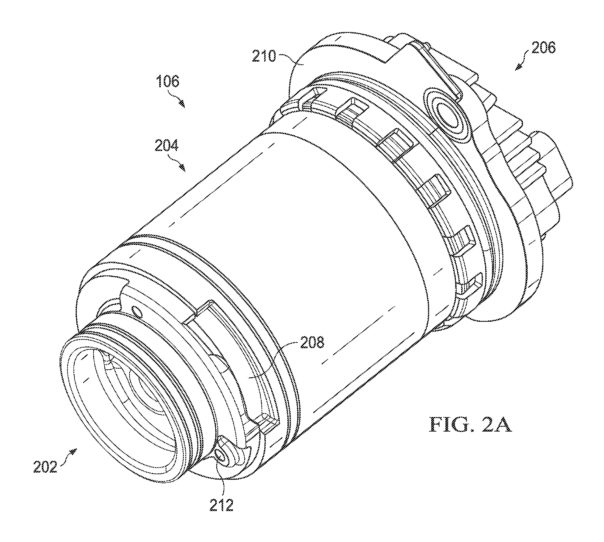

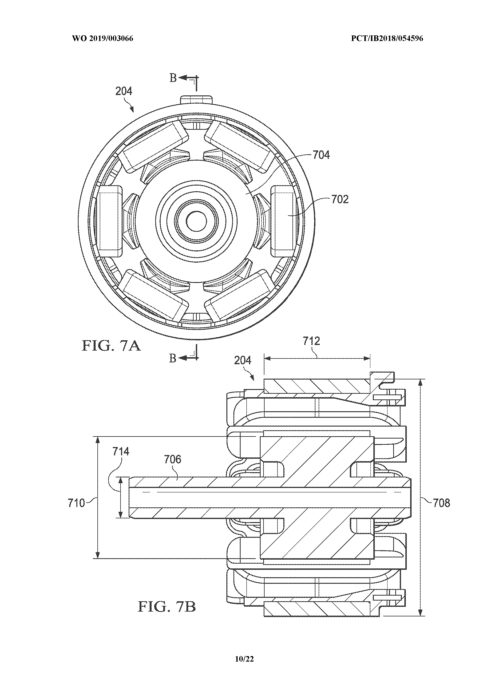

Tesla’s patent describes an electric pump system that “presents methods and structures that help overcome the difficulties of operating a cooling and lubrication system, in particular, managing the transfer of heat and assessment of fluid temperature in electric pump systems.” The Silicon Valley-based carmaker describes its electric pump system design as follows.

“There is provided an apparatus that includes an electronic control unit, a mechanical pump, and a motor having a first side and a second side, the motor including: a stator, a rotor including a hollow shaft, and a housing around the stator and rotor, wherein the electronic control unit is connected to the first side of the motor, wherein the mechanical pump is connected to the second side of the motor, wherein the hollow shaft defines a shaft inlet and a shaft outlet, wherein the mechanical pump defines a first fluid passageway from a first pump inlet to the shaft inlet, wherein the housing defines an internal motor cavity, wherein the shaft outlet is in fluid communication with the internal motor cavity, wherein the mechanical pump defines a second fluid passageway from a second pump inlet to a pump outlet, and wherein the motor housing and mechanical pump define a third fluid passageway from the internal motor cavity to the pump outlet via a third pump inlet.”

“In some embodiments the apparatus according to the above-described aspect of the present disclosure or any other aspects thereof, a number of optional operations and features may be employed. One optional feature is the electronic control unit further including a thermistor to measure a temperature of a fluid exiting the shaft outlet. Another optional feature is wherein the housing defines a bypass inlet in fluid communication with the internal motor cavity. Another optional feature is at least a portion of the second fluid passageway and the third fluid passageway is common. Another optional feature is the mechanical pump is a gerotor. Another optional feature is the electronic control unit includes a microcontroller controlling the mechanical pump. Another optional feature is the electronic control unit includes cooling ribs.”

With such a design, the fluid temperature inside the electric pump system could be used to control and optimize the lubrication system of a vehicle, thereby improving the efficiency of an electric drive unit. Depending on the temperature of the oil in the system, the electric pump could react accordingly, even warning the vehicle’s computers that something is wrong. The readings from the electric pump system can be used to monitor the health of a vehicle’s drive unit as well. Tesla explains this process in the following discussion.

“The fluid temperature may be controlled to achieve certain lubrication properties. For example, hotter oil has lower viscosity which reduces drag and hydraulic power to pump the fluid, which can increase efficiency. If the oil becomes too hot, however, it will not provide sufficient cooling. The fluid temperature reading feature of the oil pump can monitor the general health and performance of the fluid in the electric drive unit system. For example, if the oil is too hot, the oil pump may alert the car computer that something is wrong, for oil that is too hot can damage or/and reduce the life of some components on the drive unit.”

“Stated another way, the temperature of fluid may be used to monitor the health and performance of the drive unit. The ECU may capture other information besides the temperature, such as pump speed, pump current composition, oil pressure, or other information. The information captured by the ECU may then be fed into a proprietary algorithm that monitors oil pump and overall drive unit health. The algorithm may provide an indication of service, such as when oil must be replaced or when the drive train needs to be serviced.”

What is particularly notable is that these improvements could result in enhancements to Tesla’s drive units, which are already among the best in the industry. The Model 3’s drive unit, for one, has been lauded by veteran teardown experts such as Sandy Munro as industry-leading. In a recent appearance at Autoline TV, for one, Munro noted that Tesla’s drive units are practically a class above its competitors.

Tesla’s constant efforts to improve its vehicles are highlighted by the patent applications from the company that have been published over the past months. Among these include an automatic tire inflation system that hints at off-road capabilities for the company’s vehicles, a system that allows Tesla to address panel gaps during vehicle assembly, a way to produce colored solar roof tiles, and even a model that utilizes electric cars as a way to improve vehicle positioning, to name a few.